The buried scraper conveyor is a common vibrating conveying equipment for grain materials. It is a transportation equipment that continuously conveys bulk materials by means of a moving scraper chain in a closed rectangular section or circular tube section shell. Because the scraper chain is buried in the material and moves forward together with the material when it is working, it is called “buried scraper conveyor.

The buried scraper conveyor is a conveying machine with flexible traction components. Its main function is to move bulk materials forward through the traction of scraper chains to realize the conveying and accumulation of materials. The buried scraper conveyor can convey powdery, granular and small block materials in horizontal, inclined or vertical directions.

The structure of the buried scraper conveyor is reasonable, and it can be fed at multiple points and unloaded at multiple points. The scraper chain moves evenly under the transmission of the motor + reducer, with stable operation and low noise.This conveyor system is widely used in industries such as grain, light industry, and chemical industry.

Analysis of the four structural components of the buried scraper conveyor

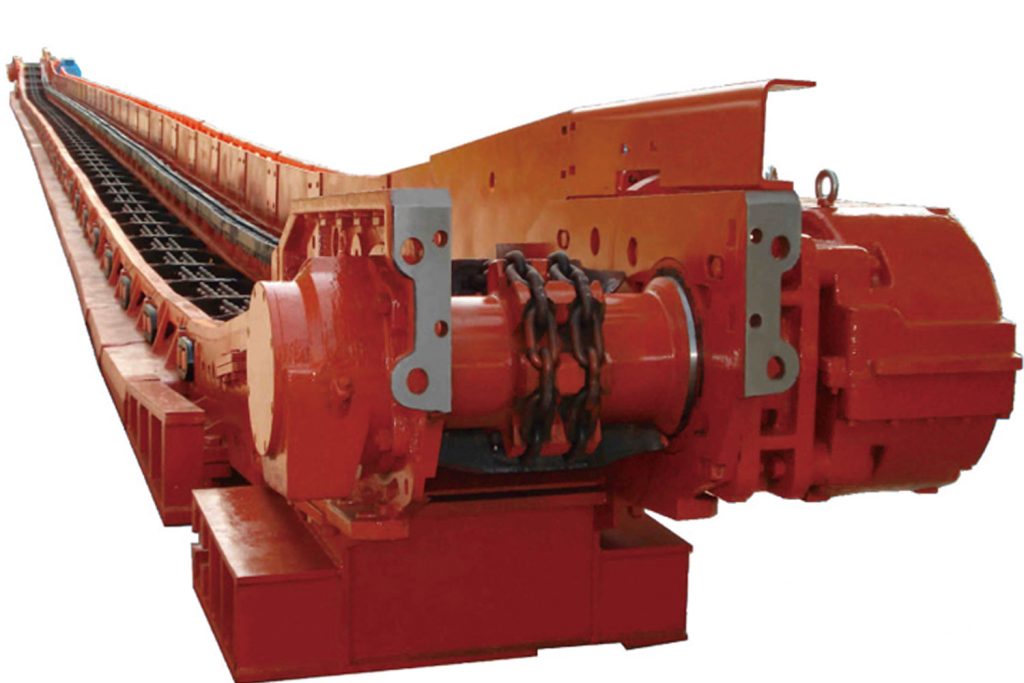

The buried scraper conveyor is composed of a closed shell (machine slot), scraper chain, driving device and tensioning device and other components.

When the buried scraper conveyor is working, the material enters the load-bearing section of the casing through the feed port, and is pushed by the scraper, and moves forward together with the scraper strip to form a whole. When the no-load section of the machine is turned back, the function of the driving device is to transmit the power of the motor to the scraper chain. The function of the tensioning device is to maintain the initial tension of the scraper chain.

Closed housing (chassis)

The main part of the buried scraper conveyor is the machine trough, which is designed with a closed structure, which can effectively prevent material leakage and environmental pollution.

The machine trough is usually made of steel plates with upward flanging, and the thickness of the bottom reinforcement steel plate is greater than that of the steel plate and the scraper chain. The steel plate in the machine tank is bent and arc-shaped to form self-supporting rigidity, which increases the bearing capacity and bending resistance of the machine tank.

scraper chain

The scraper chain is the load-bearing traction component of the buried scraper conveyor, which is composed of sliding rollers, chain plates, connecting rods and mandrels.

As a part of load transmission and chain guidance, rollers usually use copper sleeves and wheel sleeves to reduce rolling resistance; chain plates are connected to each other through connecting rods and mandrels to form links for carrying and transmitting materials. At the same time, the chain has excellent characteristics such as high strength, high toughness and wear resistance, which can meet the needs of different working environments.

drive unit

The driving device of the buried scraper conveyor is composed of a motor, a reducer and a sprocket. The motor drives the sprocket to rotate through the reducer, so that the power is transmitted to the scraper chain to make it move forward to realize the conveying of materials. At the same time, the driving device can also adopt various forms and configurations according to different working environments and requirements to meet the different needs of users.

Tensioner

The tensioning device of the buried scraper conveyor consists of an adjustment piece and a tension wheel. Wherein, the adjusting piece is used for manually or automatically adjusting the tension of the scraper chain to ensure the normal operation of the scraper chain.

The tension wheel is used to maintain the stability of the chain during movement and avoid accidents such as broken chain. At the same time, the device can also be used in various forms and configurations according to different requirements, so as to meet the needs of different working environments.

In conclusion

The buried scraper conveyor is composed of a closed shell (machine slot), scraper chain, driving device and tensioning device and other components. Among them, each component has its own unique structural characteristics and functions, and together constitute the operation system of the entire equipment.

In different working environments, users can choose suitable equipment and accessories according to different needs and requirements, so as to achieve efficient, safe and stable material transportation.