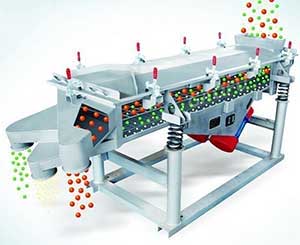

Linear vibrating screen is a high-efficiency screening equipment with a straight line motion trajectory. It uses vibration motor excitation as a vibration source to throw the material on the screen and move in a straight line. The material is separated according to different particle sizes through multiple layers of screens and discharged separately.

Five characteristics of linear vibrating screen

- Small size, light weight, simple structure, easy installation and easy maintenance.

- Low energy consumption and high output.

- High screening accuracy, large processing capacity, fully enclosed structure, no dust spillage.

- Stable and reliable, low noise and long life.

- Adopt tire coupling, flexible connection, smooth operation and high screening efficiency.

Conclusion

Linear vibrating screen is referred to as linear screen. Its main functions are grading, filtering and impurity removal. It uses two vibrating motors as vibration sources to make the material jump straight on the screen surface and enter the screen surface evenly. Materials of various specifications are produced through multi-layer rectangular screens and discharged from various outlets.

Linear vibrating screen is mainly used for dry and wet screening or dehydration, de-intermediation and de-muding of medium and fine particle materials. Linear vibrating screen is suitable for screening and grading of powdery and granular materials in coal, hydropower, mining, building materials, chemical industry, fertilizer and other industries.