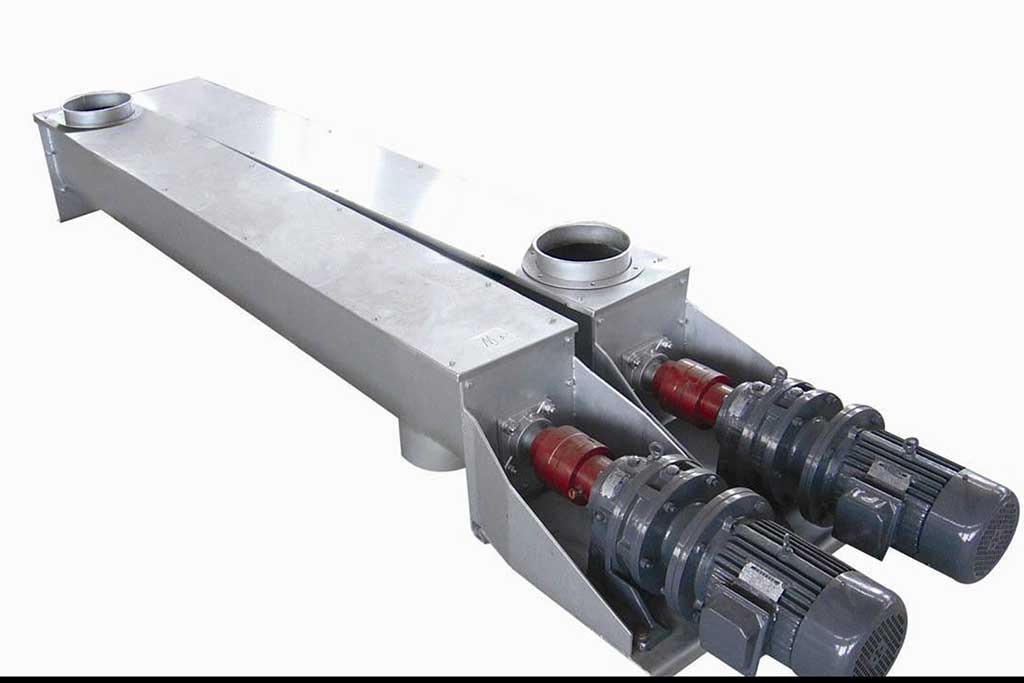

Screw conveyor is a kind of conveyor vibration system used for horizontal, inclined or vertical conveying of non-sticky powdery materials, granular materials or sheet materials, and conveying materials from one place to another.

When the screw conveyor is running, the material enters the screw shaft from the feed port, then advances through screw extrusion and rotation, and finally is discharged from the discharge port.

The horizontal screw conveyor is a vibrating conveying equipment that uses a motor to drive the screw to rotate and push the material to achieve the purpose of conveying. The conveying methods of the screw conveyor are various. It can transport materials at angles such as horizontal, inclined, and vertical. It can be transported by a single machine or a combination of multiple machines.

Six operating points of screw conveyor

- Before driving, it should be determined whether the rotation direction of the motor meets the working requirements; it should also be checked whether there are sundries in the trough, especially the blockage at the middle suspension bearing, so as to avoid blockage failure.

- The materials entering the screw conveyor should be cleaned first to prevent large pieces of impurities or fiber impurities from entering the conveyor and ensure the normal operation of the conveyor.

- When starting, it should be started without load, and when stopping, the materials in the machine should be drained before stopping.

- During the operation, if large impurities or fibrous impurities such as rice stalks and straw ropes enter the trough, stop the machine immediately. It is not possible to reach into the material trough directly by hand or with other tools to extract materials without stopping the machine.

- When conveying materials with high viscosity and high moisture content, the adherents in the machine should be cleaned frequently to avoid the decrease of the conveying capacity or even blockage.

- The top cover of the screw conveyor must be tightly closed to prevent foreign objects from entering the trough or the dust inside the machine from flying out, even causing safety accidents; at the same time, it is also forbidden to step on the cover to prevent personal safety accidents.

In conclusion

Screw conveyor is an important vibrating conveyor machine. In the process of using the equipment, it is necessary to master the correct operation method, and the operator needs to observe to ensure that the material is supplied normally, and to prevent material interruption or jamming. Pay attention to check whether the drive motor is running normally, whether the conveying capacity and transmission device are within a reasonable range, etc.

Correct operation can ensure the stability of the equipment and prolong the life of the equipment and improve production efficiency.