The screw conveyor is a general-purpose material conveying device, which mainly uses the thrust generated by the rotation of the screw blade to realize the transportation of the real material, and transports the material from the inlet to the outlet.

Screw conveyors are mainly suitable for the transportation of powdery, small and non-wet materials. They are widely used in modern industrial production, mainly in pharmaceutical, chemical, food, building materials, metallurgy and other industries.

Overview Of the 6 Major Categories Of Screw Conveyors

According to the characteristics of conveyed materials, screw conveyors are divided into different classifications. Below, we will introduce the classification and application characteristics of screw conveyors in detail.

vertical screw conveyor

The vertical screw conveyor is a kind of equipment that conveys materials along the vertical direction. It has the characteristics of simple structure, convenient installation and stable operation. It usually consists of a feed end, intermediate or multiple suspension bearings and a discharge end. Vertical screw conveyors can be designed and manufactured according to the needs of conveying capacity and conveying height.

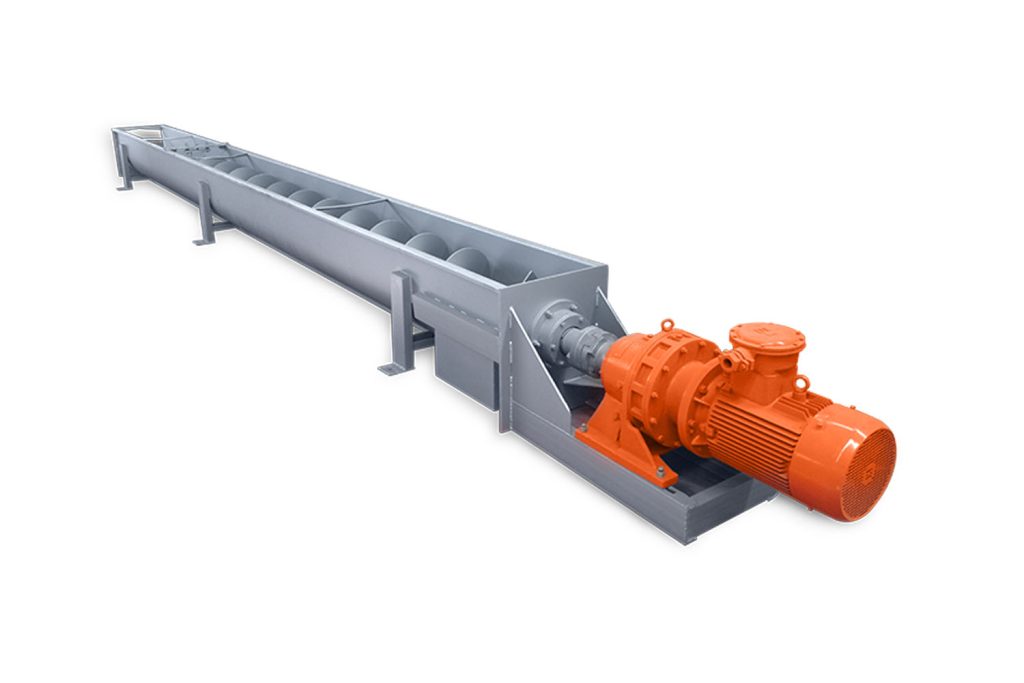

Single shaft screw conveyor

A single-shaft screw conveyor is a device that conveys materials along a horizontal or inclined direction. It usually consists of a rectangular or circular spiral blade rotating bearing, inlet, outlet and intermediate support bearings. The single-shaft screw conveyor is suitable for conveying dry powder materials such as cement, fertilizer, chemical industry and food.

Double shaft screw conveyor

The double-shaft screw conveyor is a kind of screw conveyor with horizontal double-axis symmetrical movement. It usually consists of two coaxial spiral blade rotating bearings, inlet, outlet and intermediate support bearings. The double-shaft screw conveyor is suitable for conveying viscous, easy-to-accumulate, easy-to-block materials.

Slow screw conveyor

The slow screw conveyor is a feeding equipment used to extract small-sized, high-humidity materials from the feeder. Its working principle is to move the material barrel to the discharge port of the feeder through the spiral blade. The slow screw conveyor has the characteristics of stable flow, long transportation distance and high transportation efficiency.

Hollow Screw Conveyor

The hollow screw conveyor is a device that conveys materials along the axial direction through a hollow screw shaft. It has the characteristics of quiet material transmission, smooth inner wall and easy cleaning, and is suitable for conveying easily polluted materials.

Silo Screw Conveyor

The silo screw conveyor is a material conveying system that combines storage bins, dust collectors, and conveyors. It has the characteristics of large volume, uniform material in the warehouse, and can select the discharge point in a targeted manner. It is suitable for material storage and transportation in cement, mining, chemical, building materials and other industries.

In summary

Screw conveyors have a variety of classifications, which can meet the material transportation needs of multiple industries. With the development of logistics technology, screw conveyors will be more widely used, bringing greater convenience and benefits to the logistics industry and industrial production.