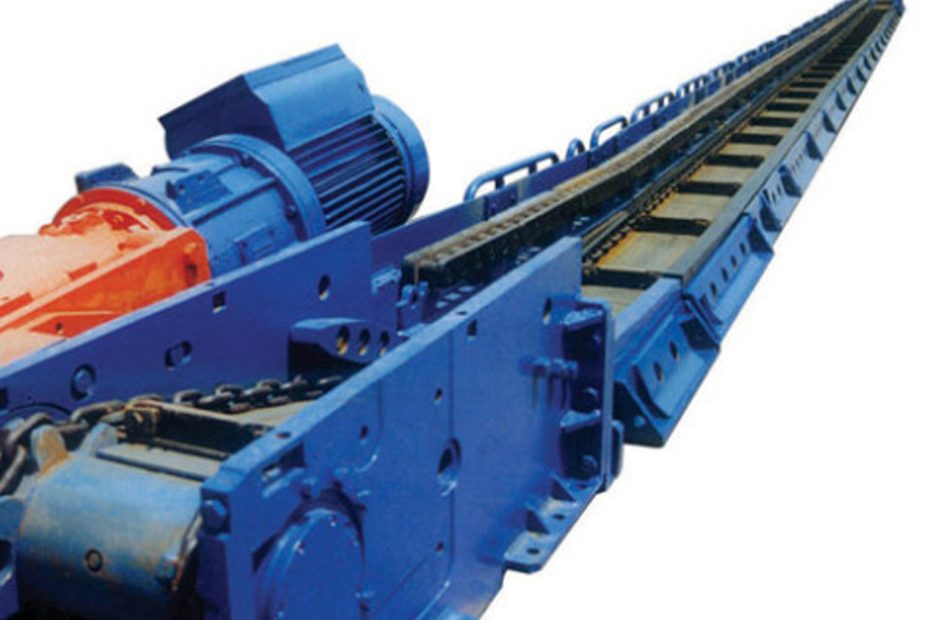

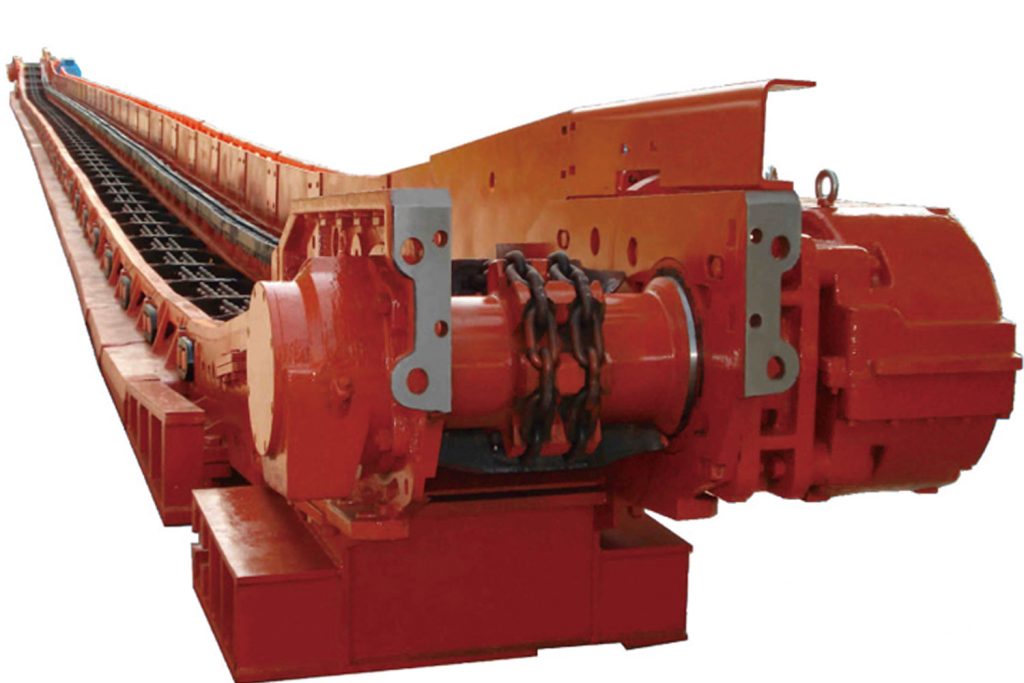

Scraper conveyor is a common conveying equipment, which is widely used in material conveying in various industrial fields. The scraper conveyor is mainly composed of scraper chain, head and tail sprocket, machine trough, feeding port, discharging port, driving device and tensioning device and other components.

Top 7 major structural components of the scraper conveyor

scraper chain

The scraper chain is one of the core components of the scraper conveyor, which is formed by connecting multiple horizontal scrapers and longitudinal chains. The function of the scraper chain is to carry, transmit power and transport materials. During the transmission process, the scraper chain is responsible for transporting the material from the feed port to the discharge port. Other components work together through the transmission of the scraper chain.

The head and tail sprocket is part of the bearing point of the scraper chain. The power of the scraper chain transmission comes from the rotation of the head and tail sprockets. The head sprocket is usually assembled on the upper part of the scraper conveyor, while the tail sprocket is installed on the lower part to ensure the stable transportation of materials.

Commonly used chains include molded satin chains, roller chains, and double-plate chains. The scraper can be divided into T type, U1 type, V1 type, O type and O4 type according to its structure. Their envelopment coefficients are different, suitable for different materials and different types of scraper conveyors. The better the scattering of conveyed materials, the scraper with larger envelopment coefficient should be selected, so as to better ensure the stable conveying of materials.

Head and tail sprockets

The head and tail sprocket is part of the bearing point of the scraper chain. The power of the scraper chain transmission comes from the rotation of the head and tail sprockets. The head sprocket is usually assembled on the upper part of the scraper conveyor, while the tail sprocket is installed on the lower part to ensure the stable transportation of materials.

The head and tail sprocket is the driving wheel and the tensioning wheel; the chain is surrounded and supported in the head and tail sprocket and the machine groove as a traction member; the scraper installed on the chain is the material conveying member. The material is conveyed in the closed machine tank through the continuously running scraper and chain.

machine slot

The machine trough is the main part of the scraper conveyor, which plays the role of sealing and supporting other components. A scraper chain is placed in the machine tank to complete the conveying of materials. Machine troughs are generally divided into two types: fixed and mobile. The fixed machine trough is suitable for fixed material conveying lines, while the mobile machine trough is suitable for places where the conveying direction and position need to be changed frequently.

The trough of the scraper conveyor can be divided into the head section, the tail section, the transition section, the bending section, the middle section (including the horizontal and vertical middle sections) and the feeding section. Among them, the curved section refers to the curved transition section from horizontal to vertical or vertical to horizontal of MC type and MZ type scraper conveyor, and its structure is more complicated; the middle section is the most basic part of the machine groove;.

Inlet

The feed port is the position where the material enters the scraper conveyor, generally located at the upper part of the machine trough. At the material inlet, the material is brought into the scraper conveyor through transportation equipment, such as belt conveyor or screw conveyor, and then transported to the discharge port sequentially by the scraper chain for discharge treatment.

Discharge port

The discharge port is the position where the material is discharged from the scraper conveyor, generally located at the lower part of the machine trough. The material moves down along the machine trough through the scraper chain, and is discharged after reaching the discharge port to complete the whole process of material conveying.

drive unit

The driving device is installed at the end of the head drive wheel, which is the driving force source of the scraper conveyor, and its function is to provide power for the scraper chain to promote its operation. The driving device of the scraper conveyor usually adopts a combination of a motor and a reducer in order to output an appropriate torque and speed, thereby facilitating the transportation of materials.

Tensioner

The tensioning device of the scraper conveyor is set at the end of the tensioning wheel at the tail, which is a device to ensure the tension of the scraper chain. Its main function is to adjust the tightness of the scraper chain by tensioning the chain. During the operation of the scraper conveyor, the tensioning device plays a role in stabilizing the conveying.

Summary

Scraper conveyor is an efficient and reliable material conveying equipment. Its main components include scraper chain, head and tail sprocket, machine trough, feeding port, discharging port, driving device and tensioning device, etc., which are coordinated with each other. function, and jointly complete the task of conveying materials.