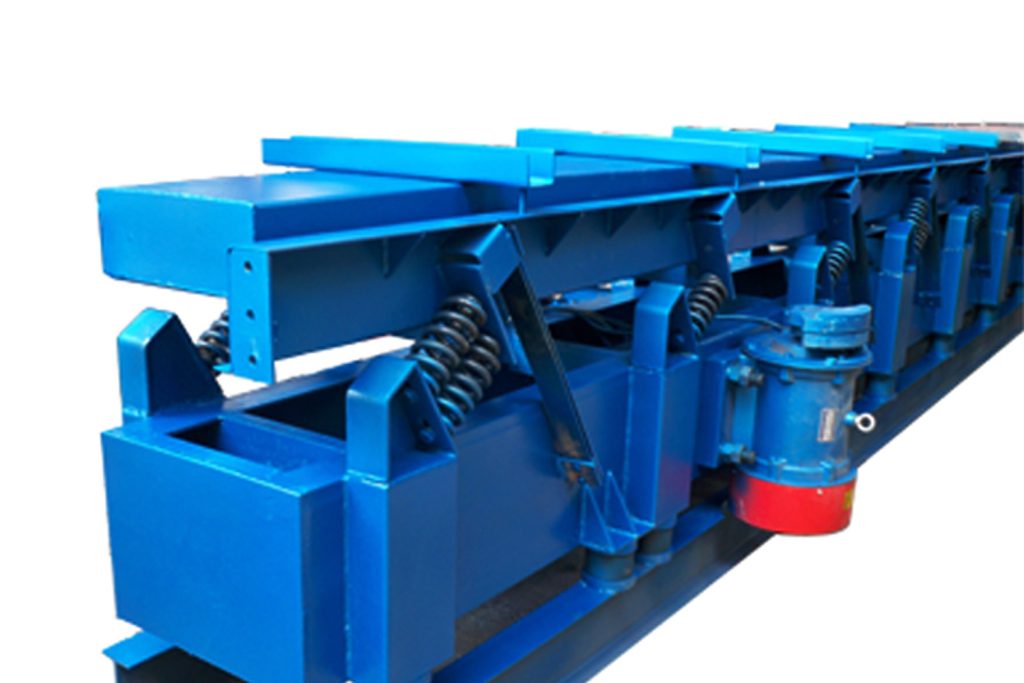

A vibrating conveyor is a material conveying device that uses vibration force to convey materials from one point to another. It is very common in various fields, including mining, chemical industry, food, building materials, etc.

Vibrating conveyors can be used to convey granular and powdery materials. If the material is fed unevenly, it can quickly distribute the material evenly on the surface of the trough to achieve a uniform conveying state. Therefore, the vibrating conveyor can also be used as a feeding mechanism and a grain cleaning and grading mechanism.

In the grain warehouse factory, the vibrating conveyor is mainly used in the occasions where the conveying volume is small, the layout space of the workshop equipment is small, it is not suitable to use belts, scrapers and screw conveyors, and the equipment feeding mechanism and accompanying materials that require uniform feeding In the process of material conveying and process requirements such as screening, heating, drying or cooling.

Three steps in the working process of the vibrating conveyor

When the vibrating conveyor is working, the conveying trough moves forward, relying on the friction of the material on the trough to make the material and the trough move forward at the same time; when the conveying trough moves backward, the friction of the material on the surface of the trough is not enough Make the material move backward together with the trough, and continue to move forward by the action of the material inertia force, so that the purpose of conveying the material can be achieved by continuously alternating reciprocating motion.

The working principle of the vibrating conveyor can be divided into three steps: start-up phase, continuous working phase and shutdown phase.

Start-up phase

Firstly, the vibrating motor needs to be started. Through the spring support at the bottom of the tank and the reasonable setting of the guides, the vibration generated by the vibrating motor can be transmitted to the conveyed material by the conveying tank to make it flow.

At this time, the material begins to flow, and under the action of the vibration force, the material moves forward along the conveying tank until it reaches the feeding port.

Continuous working stage

During the continuous operation of the vibrating conveyor, the vibrating motor continuously generates vibrations, which makes the materials inside the conveying tank flow, thereby realizing the conveying of materials. At the same time, under the action of vibration force, the solid state of the material rubs against each other to generate a certain amount of heat. And the size and direction of the vibration force can be adjusted according to the characteristics of different materials and work requirements. In addition, the function of the spring support is to offset the adverse effects caused by the vibration and ensure the smooth movement of the conveying tank.

Shutdown phase

When the vibrating conveyor stops working, first turn off the vibrating motor. Then wait for the material to stop flowing naturally before cleaning or disassembling the conveying tank.

In short

It should be noted that due to the influence of factors such as the fluidity and viscosity of the material, its movement law in the vibrating conveyor is not completely controllable and predictable.

In order to ensure the normal operation of the equipment and maximize the efficiency of material conveying, it is necessary to clarify reasonable working parameters and operating methods through a combination of practice and theoretical analysis.

In addition, the conveyor system needs regular maintenance, replacement of wearing parts and lubricating oil, etc., and safety regulations should be paid attention to during use to avoid equipment failure and ensure production efficiency and production safety.