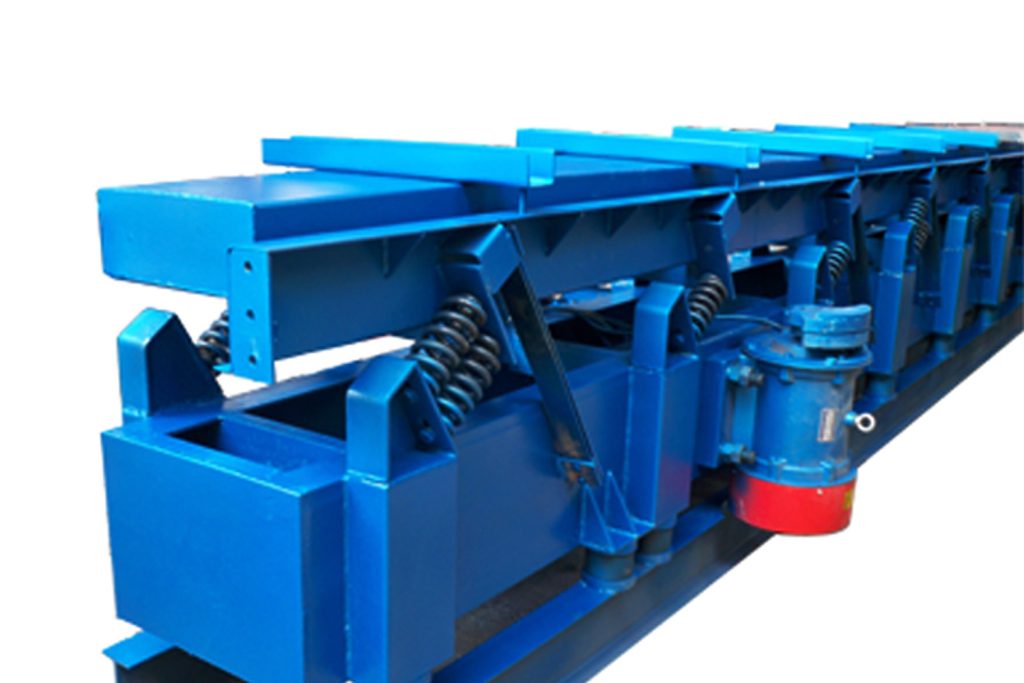

Vibrating conveyors are primarily used for the transportation of bulk, granular, or powdered materials, such as chemicals, food, cement, glass raw materials, ores, concentrates, coal, foundry sand, machine parts, and tobacco. They find applications in various industries, including dry ore beneficiation plants, steel plants, foundries, carbon plants, chemical plants, pharmaceutical plants, cement plants, food processing plants, and mechanical factories.

Characteristics of Vibrating Conveyors

Compared to other types of conveyors, vibrating conveyors possess the following distinctive features:

- Excellent Sealing Capability: Vibrating conveyors can achieve effective dust prevention economically. This sets them apart from other conveyors. For example, though belt conveyors can be sealed with dust covers, they consume more steel, occupy larger space, add weight and cost, and still expose machine components to dusty environments, leading to inconvenient maintenance and reduced lifespan. Similarly, en-masse conveyors and screw conveyors, though offering relatively better sealing, suffer from significant wear on certain components, resulting in shorter lifespans. On the contrary, vibrating conveyors can be designed in circular or rectangular shapes, and as materials advance through the conveyor, they jump slightly, causing minimal wear and maintaining effective dust prevention.

- Transportation of High-Temperature or Hazardous Materials: Belt conveyors are not suitable for transporting high-temperature materials as the belts cannot withstand high temperatures. Additionally, en-masse conveyors and screw conveyors cannot operate at high temperatures because the lubricating oil will become thinner and flow outside the bearings, causing poor lubrication. However, vibrating conveyors can handle materials at around 500°C when using air cooling and approximately 1000°C when using water jackets.

- Facilitates Various Processes: While conveying materials, vibrating conveyors can conveniently carry out cooling, drying, dewatering, screening, mixing, insulation, heat insulation, and moistening processes simultaneously.

Top 4 Applications of Vibrating Conveyors

Vibrating conveyors are widely used in industries requiring dust prevention and transportation of high-temperature, hazardous, or toxic materials. Some common applications include:

- Dust Prevention: In situations where dust prevention is crucial, such as handling fine powders or hazardous materials, vibrating conveyors are the preferred choice.

- High-Temperature Material Transport: Industries dealing with materials at high temperatures, like the steel and cement industry, benefit from using vibrating conveyors to transport hot materials effectively and safely.

- Foundry and Metal Casting: Vibrating conveyors efficiently transport foundry sand and castings, contributing to smoother and automated casting processes.

- Mining and Mineral Processing: In mining operations, vibrating conveyors handle ores, concentrates, and tailings, simplifying material transportation.

Top 3 Comparison of Conveyor Types

| Conveyor Type | Dust Prevention | High-Temperature Material Transport | Ease of Multiple Processes |

|---|---|---|---|

| Vibrating Conveyor | Excellent | Yes | Yes |

| Belt Conveyor | Moderate | No | No |

| En-Masse Conveyor | Relatively Good | No | No |

| Screw Conveyor | Relatively Good | No | No |

Advantages of Vibrating Conveyors

Apart from the features mentioned above, vibrating conveyors offer several other advantages:

- Simplicity of Structure: Vibrating conveyors have simple structures, making them easy to manufacture, install, and adjust.

- Convenient Maintenance: These conveyors require minimal maintenance, leading to reduced downtime and operational costs.

- Energy-Efficient: Vibrating conveyors consume relatively less energy, making them economical in the long run.

- Enhanced Safety: Their design promotes safe operation, ensuring the safety of workers and materials being conveyed.

Conclusion

Vibrating conveyors stand out as a versatile and advantageous choice for material transportation, especially in scenarios where dust prevention, high-temperature material handling, and multiple processes are essential.

Their superior sealing capability, ability to transport hazardous materials, and convenience in multiple processes make them indispensable in various industries. While considering conveyance solutions, industries seeking efficient, durable, and low-maintenance systems often turn to vibrating conveyors for their unique advantages and wide-ranging applications.