Five Application Areas Of Belt Conveyor

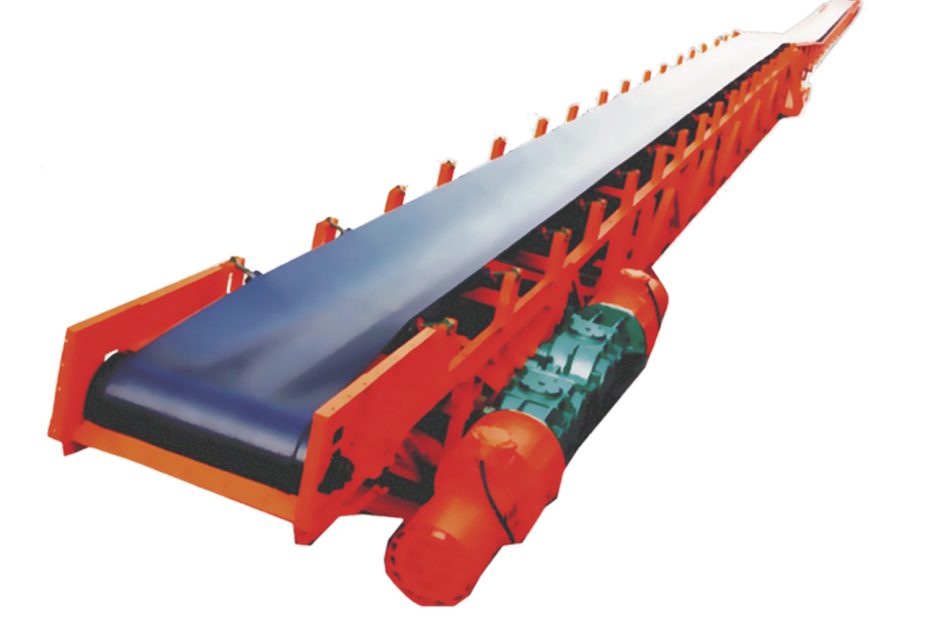

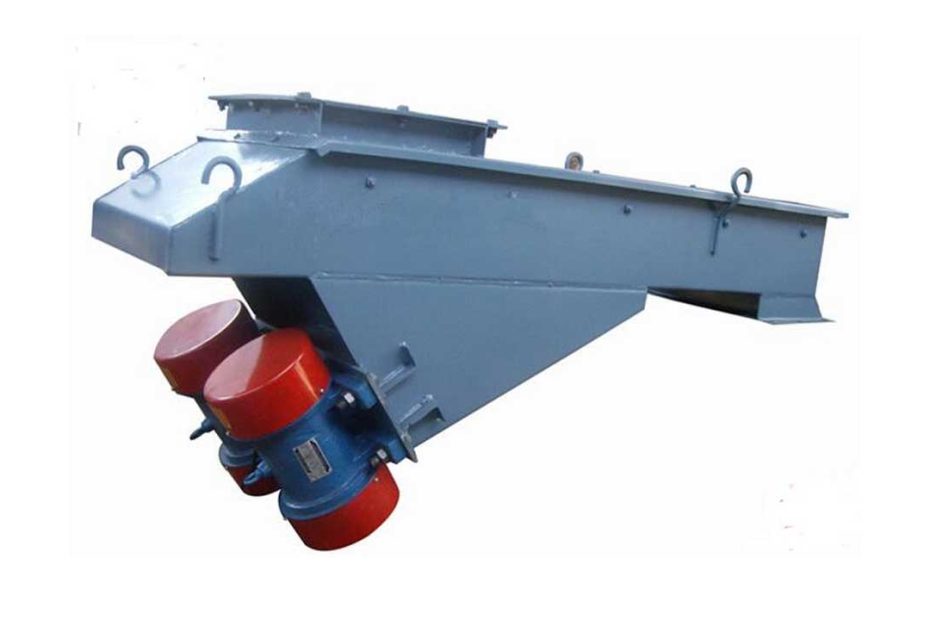

As a common material conveying equipment, belt conveyor is widely used in mining, metallurgy, coal, cement and other industrial fields.Because of its large span, high conveying capacity, economical and practical characteristics, it has been widely used.