Enhancing Industrial Automation With Electromagnetic Vibrating Feeders : Top 5 Advantages And

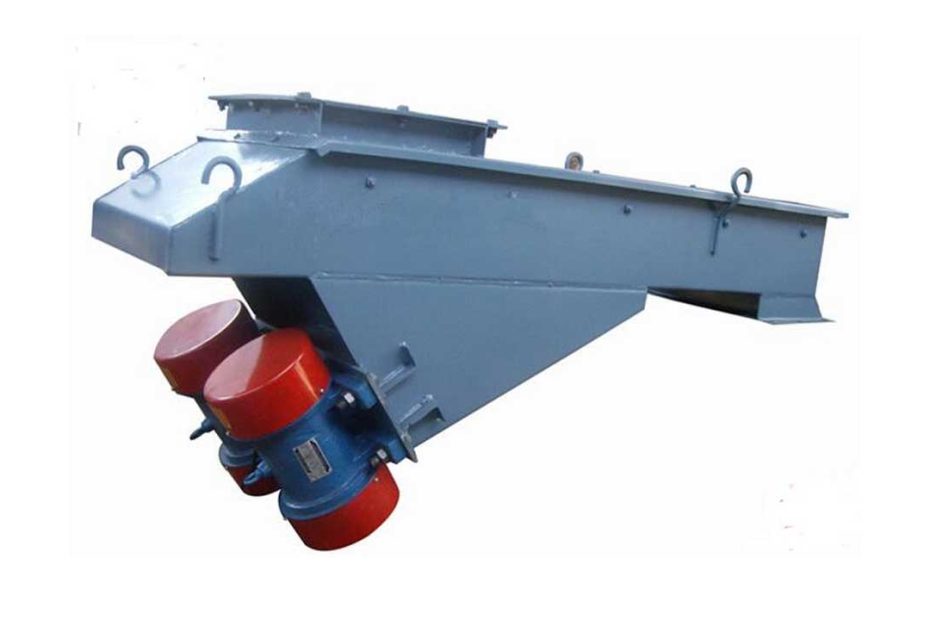

Electromagnetic vibrating feeders simplify industrial material supply.Their stable operation and low power consumption enhance reliability and cost-efficiency.